Kókai és Társa Ltd. has been dealing with engineering design, target machine production since 1998 and later injection molding. In addition to manufacturing conventional injection molding machines there was an increasing demand for the production of small plastic parts and a suitable manufacturing machine and tool. The result of the development work was the mini injection molding machine, which not only simplified production, but also a cost-effective, innovative machine was created.

Making small tools

What is the Mikromold?

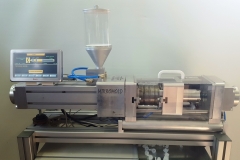

The Mikromold Injection Molding Machine is a clean, electrically driven, innovative manufacturing tool which is suitable for the unique and series production of small plastic components. Its construction and control is simple and user-friendly.

MIKROMOLD

injection molding machine

Products

What are the main

parameters of the machine?

- Closing force: 30kN

- Piston diameter: 20mm

- Dose: cca15g

- Tool: 75x75x80mm

- Heating: 500W

- Injection pressure: max.700bar

- Energy needs: 230V; 50Hz

- Materials used: general plastics + macromelt

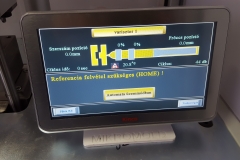

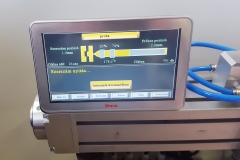

- Control: Card PC

- Treatment: 7-inch touch screen

- Data management: save 40 program

What types of machines exist?

Who we offer to?

Those who want to manufacture small parts in a cost effective way, from prototype up to larger volumes. Due to the small space requirement it is ideal for those who only have a small workshop. Those who don't have plastic processing machine but want to manufacture small components.

Contact:

Telefon: +3620/2205911

E-mail: mikromold@kokaiestarsa.hu

Web: www.kokaiestarsa.hu

Innovative solution in injection molding! Mikromold for the cost-effective production of small parts!

Vertical machine

Horizontal machine

What is manual Mikromold?

Hand operated simple injection molding tool. Controlling only extends to temperature control. Due to the simplicity of the machine's design and electronics it is extremely cheap and efficient to produce simple and small volume parts.

What are the main parameters

of the machine?

- Piston diameter: 14mm

- Dose: cca7-8g

- Heating: 250W, regulated

- Energy needs: 230V; 50Hz

- Materials used: PP, PE, PA, ABS, POM, Macromelt, and so on...